As the manufacturing sector moves toward data-driven solutions and next-generation technologies, more companies are adopting digital twins to improve their business operations. But what exactly is a digital twin, and how can it benefit your business? There are several applications for digital twin technology.

What is a Digital Twin?

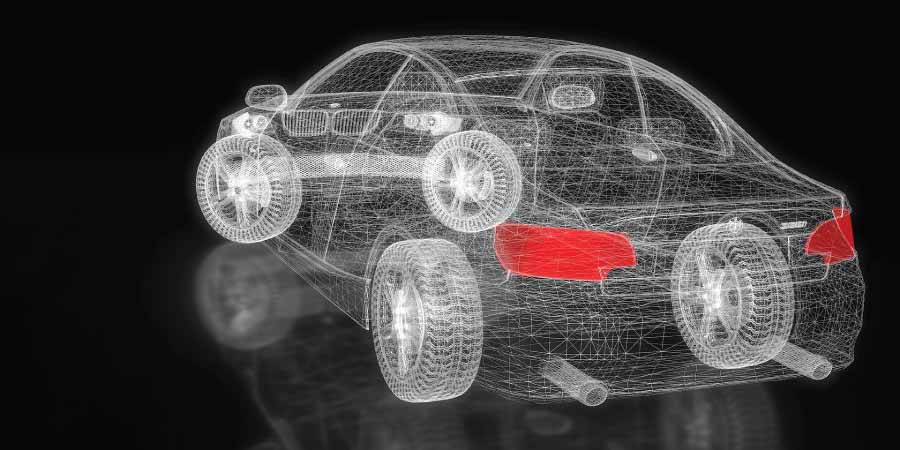

A digital twin is a virtual replica of a physical object, process, or system that can be created using data from sensors, machines, and other integrated sources. Digital twins are powerful tools that leverage augmented reality (AR) to simulate, monitor, and optimize the performance of their real-world counterparts. Digital twins can harness the power of artificial intelligence (AI) and the internet of things (IoT), allowing businesses to identify inefficiencies and improve their operations with concrete data. In the context of manufacturing logistics, a digital twin can be used to create a virtual model of a product, warehouse, or supply chain.

Product Digital Twins

A product digital twin is a virtual model of a physical product. It can be used by engineers during the product development stage to test different designs and configurations, and to simulate product performance under specific conditions. Product digital twins can help businesses reduce time to market by providing a single source of truth for all stakeholders while updates are being made. They can also help reduce prototyping and testing costs by simulating how a product will function in the real world and identifying potential issues before the product is manufactured.

In the automotive industry, manufacturers have begun to use digital twin technology to revolutionize the way cars are made. Since 2022, automotive manufacturer Renault Group has used virtual models in its design and engineering stages to conduct preliminary tests through simulation before creating a physical model for further testing. Since real automotive prototypes are expensive and time-consuming to produce, using digital simulations early in the process helps reduce costs, resources, and time to market by as much as 25%. Data gathered from the physical prototype tests is incorporated into the final product digital twin so it can be used to manufacture vehicles

Supply Chain Digital Twins

A supply chain digital twin is a virtual model of a process with multiple touchpoints including suppliers, manufacturers, and distributors. It can be used to simulate the movement of goods to different locations, optimize inventory levels, and identify potential supply chain bottlenecks or disruptions. The supply chain digital twin considers factors like demand, lead times, and shipping costs to simulate different scenarios for inventory levels and transportation routes. By analyzing the data generated by a supply chain digital twin, companies can identify the most effective strategies for supply chain network optimization and prepare for potential disruptions, while reducing costs and improving delivery times. A supply chain digital twin can provide valuable insights into complex supply chain operations, allowing businesses to improve their planning and decision-making, reduce costs, and manage risks effectively.

Warehouse Digital Twins

A warehouse digital twin is a virtual replica of a physical warehouse that can be used to simulate the layout and flow of goods within a warehouse. Warehouse digital twins can be powerful tools for optimizing inventory management and increasing warehouse process efficiency. Through digital warehouse simulations, businesses can run what-if scenarios to determine the effects that layout changes or swings in supply and demand will have on physical warehouse operations. By implementing a warehouse digital twin, companies gain insight into their layout and picking operations, reduce downtime by optimizing warehouse processes, and make informed decisions in response to supply and demand changes.

Consider a warehouse that manages e-commerce business inventory. The warehouse has many SKUs, and picking can be time-consuming and error-prone without an optimized warehouse layout. A digital twin warehouse simulation can help optimize inventory slotting to reduce the time and cost required to pick items. The warehouse digital twin can simulate different scenarios for inventory placement by incorporating item popularity, SKU affinity, picking frequency, and storage capacity to identify the most efficient warehouse space usage. The digital warehouse can also consider item location and pick density to identify optimal picking routes, reducing picking time and effort.

Implement a Warehouse Digital Twin Solution

For manufacturers, distributors, and retailers, a warehouse digital twin is a powerful tool that can help businesses stay competitive in today’s highly competitive and rapidly changing marketplace. By using warehouse simulation software, businesses can reduce costs, optimize warehouse space, and improve operational efficiency. Contact us today to schedule a demo and discuss how a warehouse digital twin could be right for you.